|

No

Escape From the Labyrinth™ Marking, engraving, welding and cutting lasers all generate hazardous dust and fume that should be controlled by an extraction and filtration system. The cost of ownership of these systems in terms of replacement filters can be a concern for the end user. The new patented Labyrinth™ filter from Purex may just be the answer. |

|

Current

technology |

(Fig-1) |

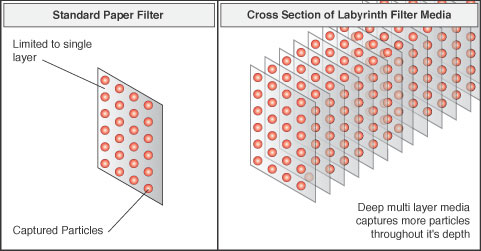

The Labyrinth filter is a radical departure from current 'off the shelf' filters and has been specifically designed for filtration of laser fume. (Fig-1) shows how a paper filter can only capture particles on a single thin face of media whereas the multi layered Labyrinth filter media is deep and graded and so has a much greater dust holding capacity throughout without affecting airflow. The greater dust holding capacity means that the end user does not have to change the filter as often and therefore laser dowtime is kept to a minimum and because they buy fewer filters, the annual cost of replacements is much lower, in some cases over 10 times less. Further savings are made by the customer in shipping costs, as compared to bulky rigid filters which may be expensive to transport, the Labyrinth is small, compact and lightweight and less likely to be damaged in transit. (fig-2) |

|

• Small

|

| Electro-Cell

technology Electro-Cell technology locks particles within the filter by actively attracting dust particles to the media fibres. The unique design of the filter pockets also allows multi-directional airflow, further increasing the performance of the filter. |

Another

positive and important point for the customer is that Purex machines

are front loading, so the operator can simply open the door and

push the small replacement filter into place in seconds without

having to disconnect the machine from the process. Although small

for shipping and storage purposes, the Labyrinth filter delivers

massive performance once inside the machine. (fig-3) shows

just how much filter media is used in the new design. |

(Fig-3) |

of Paper Pleated Filters and Bag Filters |

Purex Labyrinth Filter |

| Some

pleated paper filters need to be large and bulky in order to be

effective More working area needed to change filters Bad design when a small operating footprint is required |

The Labyrinth is exceedingly compact - also means the Purex unit has a very small operating footprint |

| Filter media only captures dust particles on a single thin face | Multi-layered filter media captures up to 20 times the quantity of dust particles |

| Some pleated paper filters need to be large and bulky - increase shipping and storage costs for customer | Can be posted anywhere in the World for a fraction of the cost to the customer |

| Bag filters - Area of media limited to keep the bag small - short lifespan | A full 20 multi-layered sections of filter media to capture particles ensures very long life - very low cost of ownership |

| Filters require regular replacement | During extensive trials Labyrinth filters have been proven to have a very long life which means a low cost of ownership |

| General 'off the shelf' filters can vary in quality | Specifically designed and evaluated by Purex Engineers and tested by leading laser OEMs |

Some

extraction units using paper filters load from the back yet have

controls at the front |

Purex

units have a footprint of less than 0.5m All controls and filter changes are accessed at the front Saves valuable space, also filters are changed in seconds without disconnecting or moving the machine! |

|

| -

FREE - Fume Extraction Guide |

|

Purex are proud to be members of... |

The Laser Institute of America |

The Association of Industrial Laser Users |

| If

you sell or use lasers to mark, engrave, weld or cut then we

can offer a filtration solution for laser fumes Email your enquiry here |